Showing all 15 results

1.5L Super-Alloy High Pressure Reactor Max.1000C - GSL-1100X-NI-1500

GSL-1100X-NI-1500 is a 1500 mL vertical furnace ( reactor) made of Ni-based Superalloy, which has excellent creep strength and anti-oxidation. It can reach 1000 °C with a pressure of up to 1 MPa under oxygen or inert gasses. It is an ideal tool for preparing advanced material by the hydrothermal method, especially for heat treatment of samples under high oxygen pressure. A solenoid valve is installed on the flange for automatic pressure relief control. Temperature control and pressure monitoring software are included for remote control. It also can be used as a steam generator.

GSL-1100X-NI-1500 is a 1500 mL vertical furnace ( reactor) made of Ni-based Superalloy, which has excellent creep strength and anti-oxidation. It can reach 1000 °C with a pressure of up to 1 MPa under oxygen or inert gasses. It is an ideal tool for preparing advanced material by the hydrothermal method, especially for heat treatment of samples under high oxygen pressure. A solenoid valve is installed on the flange for automatic pressure relief control. Temperature control and pressure monitoring software are included for remote control. It also can be used as a steam generator.

100ml Hydrothermal Reactor up to 4MPa Optional for SS316 or Ti w/ Heating - GSL-500X-XX

$1,198.00 – $3,498.00Price range: $1,198.00 through $3,498.00

GSL-500X-XX is a mini reactor made of pure titanium or SS316 steel. It can reach pressure up to 4 Mpa max. Heater and digital temperature are optional to heat the reactor up to 400ºC for the Ti vessel and 500ºC for the SS 316. It is an ideal tool for preparing advanced materials, especially bio-materials by the hydrothermal method.

GSL-500X-XX is a mini reactor made of pure titanium or SS316 steel. It can reach pressure up to 4 Mpa max. Heater and digital temperature are optional to heat the reactor up to 400ºC for the Ti vessel and 500ºC for the SS 316. It is an ideal tool for preparing advanced materials, especially bio-materials by the hydrothermal method.

1100°C Vacuum Crucible Furnace with 4"OD x 8" H Quartz Chamber - VBF-1200S-VC

VBF-1200S-VC is a vacuum crucible furnace with a quartz tube of 4"OD x 3.7"ID x 8"L and a flange for sintering a sample up to 3" under vacuum. The trring function is available as an option

VBF-1200S-VC is a vacuum crucible furnace with a quartz tube of 4"OD x 3.7"ID x 8"L and a flange for sintering a sample up to 3" under vacuum. The trring function is available as an option

1200°C 3-Zone Fixed/Fluidized Bed Furnace for Methane Reforming and Fischer-Tropsch Reactions- OTF-1200X-III-HP-VT

OTF-1200X-III-HP-VT is a three-heating zone (900 mm L) vertical fluidized bed furnace with 1200°C max (1100°C continuous) working temperature and two 60mm dia. processing tubes, which can be used to test catalysts for methane reforming (hydrogen and syngas production) and Fisher-Tropsch (hydrocarbons synthesis) reactions.

OTF-1200X-III-HP-VT is a three-heating zone (900 mm L) vertical fluidized bed furnace with 1200°C max (1100°C continuous) working temperature and two 60mm dia. processing tubes, which can be used to test catalysts for methane reforming (hydrogen and syngas production) and Fisher-Tropsch (hydrocarbons synthesis) reactions.

1200°C Vertical Split-able Furnace for DIY Tubular Reactor (1- 2" Dia.) w/ Temperature Controller - OTF-1200X-SVN

$2,698.00 – $2,798.00Price range: $2,698.00 through $2,798.00

Transported by LTL Freight (Truck)

Transported by LTL Freight (Truck)

500°C Ti Metal Reactor with 6 Feedthroughs for Molten Salt Electrolyze or Battery - VBF-600Ti

Transported by LTL Freight (Truck)

Transported by LTL Freight (Truck)

600°C SS316 Alloy Reactor with 6 Feedthroughs for Molten Salt Electrolyze or Battery - VBF-600S

VBF-600S is a compact top-loading furnace with an SS316 vessel. It is designed for studies of molten salt electrolyzers or batteries. The top flange with six 1/4" tube feedthroughs can be used as gas inlet, gas outlet, electrode feedthrough, and temperature feedthrough.

VBF-600S is a compact top-loading furnace with an SS316 vessel. It is designed for studies of molten salt electrolyzers or batteries. The top flange with six 1/4" tube feedthroughs can be used as gas inlet, gas outlet, electrode feedthrough, and temperature feedthrough.

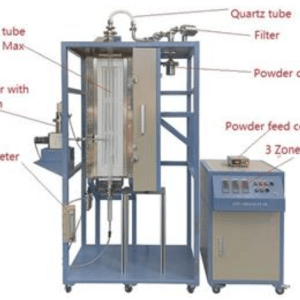

Continuous Fluidized Bed Furnace up to 1200℃ with Powder Feeding and Collecting - OTF-1200X-III-VT-FB

OTF-1200X-III-VT-FB is a continuous fluid bed system up to 1200℃ with three zine heating tube furnaces and an 80 mm OD quartz reactor. powder feeding and powder collecting functions are integrated into the system to achieve particle coating for various materials.

OTF-1200X-III-VT-FB is a continuous fluid bed system up to 1200℃ with three zine heating tube furnaces and an 80 mm OD quartz reactor. powder feeding and powder collecting functions are integrated into the system to achieve particle coating for various materials.

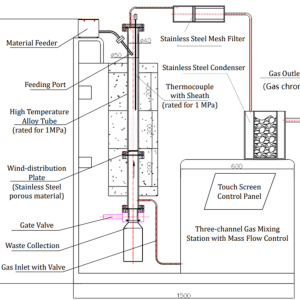

Converting Waste Plastic to Flammable Gases: Hi-Pressure Fluidized Bed Pyrolysis Reactor - OTF-1200XII-FB

OTF-1200X-FB is a Hi-Pressure Fluidized Bed Pyrolysis Reactor for the research on converting waste plastic into flammable gas.

OTF-1200X-FB is a Hi-Pressure Fluidized Bed Pyrolysis Reactor for the research on converting waste plastic into flammable gas.

Fluidized Bed CVD (FBCVD) Furnace with 1" O.D Quartz Tube and Flange for Powder CVD - OTF-1200X-S-FB

OTF-1200X-S-FB is a UL/CSA ready to pass and a Fluidized Bed Vertical Furnace with 1'' O.D Quartz Tube (2'' O.D enlarged central area) for powder CVD ( FBCVD)applications. It consists of a vertical positioned cylindrical heating chamber that surrounds the quartz tube with a built-in filter right in the lower middle section of the central heating zone. Its filter is a porous (15~40 microns) quartz frit that allows the controlled gas flow passes through and floats the particles on a cushion of the gas stream where the interaction between the solid and gaseous materials takes place.

OTF-1200X-S-FB is a UL/CSA ready to pass and a Fluidized Bed Vertical Furnace with 1'' O.D Quartz Tube (2'' O.D enlarged central area) for powder CVD ( FBCVD)applications. It consists of a vertical positioned cylindrical heating chamber that surrounds the quartz tube with a built-in filter right in the lower middle section of the central heating zone. Its filter is a porous (15~40 microns) quartz frit that allows the controlled gas flow passes through and floats the particles on a cushion of the gas stream where the interaction between the solid and gaseous materials takes place.

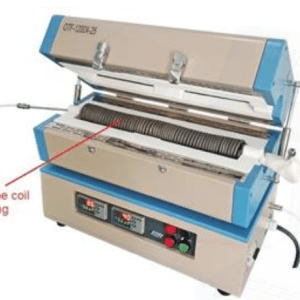

Gas Pre-Heating Tube Furnace up to 700oC @ 15L/m Flow Rate For Pyrolysis Reactors- OTF-1200X-25

OTF-1200X-25 is a gas pre-heating furnace for various pyrolysis reactors with hot gas outlets up to 700oC at a 15L/minute flow rate.

OTF-1200X-25 is a gas pre-heating furnace for various pyrolysis reactors with hot gas outlets up to 700oC at a 15L/minute flow rate.

Hi-Pressure Fluidized Bed Furnace/ Reactor ( 3 bar @1100oC) w/ 1“ID Super-Alloy Tube - OTF-1200X-S-SB

Transported by LTL Freight (Truck)

Transported by LTL Freight (Truck)

Hi-Pressure Fluidized Tubular Reactor up to 1000oC and 20 MPa - OTF-1200X-NS-FB

OTF-1200X-NS-FB is a three-heating zone (1200 mm L ) tubular reactor/reactor with 1000oC max working temperature and optional pressure up to 25 Mpa.

OTF-1200X-NS-FB is a three-heating zone (1200 mm L ) tubular reactor/reactor with 1000oC max working temperature and optional pressure up to 25 Mpa.

High-Pressure Vessel (Autoclave) Max. 20 MPa up to 200C, Optional 3, 5, or 10 L - HPV-LH

HPV-LH is a high-pressure vessel (Autoclave) with a heating jacket, which can reach pressure up to 20 MPa and working temperature up to 200°C. The vessel has a standard 3-liter volume and optional vessels are available with higher volumes.

Note: Upgrade the equipment with safety cover since Sept 2022

Note: Upgrade the equipment with safety cover since Sept 2022

HPV-LH is a high-pressure vessel (Autoclave) with a heating jacket, which can reach pressure up to 20 MPa and working temperature up to 200°C. The vessel has a standard 3-liter volume and optional vessels are available with higher volumes.

Note: Upgrade the equipment with safety cover since Sept 2022

Note: Upgrade the equipment with safety cover since Sept 2022

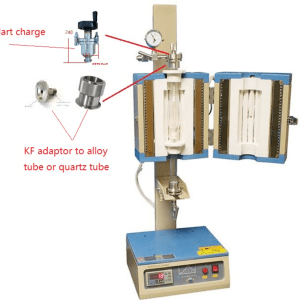

Super-alloy High Pressure Hydro-thermal Reactor 1100C, Optional 65ml & 100ml - GSL-1100X-RC series

RC-Ni is a reactor made of Ni-base Superalloy, which has excellent creep strength and anti-oxidation. It can reach 1100 °C with a pressure of up to 4Mpa under oxygen or inert gas. It is an ideal tool for preparing advanced materials by the hydrothermal method, especially heat treatment samples under high oxygen pressure. A solenoid valve is installed on the flange allowing auto-pressure relief control. Temp. Control and Pressure Real-time Monitoring software are also included. (new feature since 5/12/14) . The reactor also can be used as a steam generator

RC-Ni is a reactor made of Ni-base Superalloy, which has excellent creep strength and anti-oxidation. It can reach 1100 °C with a pressure of up to 4Mpa under oxygen or inert gas. It is an ideal tool for preparing advanced materials by the hydrothermal method, especially heat treatment samples under high oxygen pressure. A solenoid valve is installed on the flange allowing auto-pressure relief control. Temp. Control and Pressure Real-time Monitoring software are also included. (new feature since 5/12/14) . The reactor also can be used as a steam generator