Product details

SPECIFICATIONS

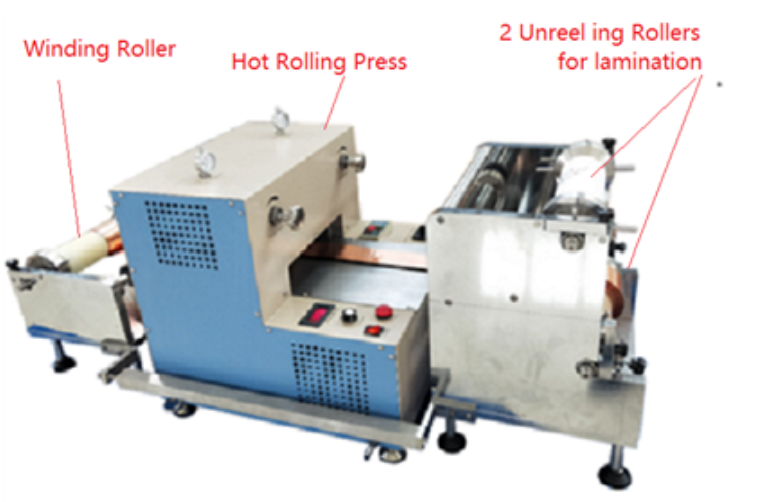

Features | Building two 8″ W feeding rollers and one winding roller for either one layer rolling or two layers of laminatingRoll to roll feeding with automatic tension control with optional alignment functionAdjustable pressing thickness up to 2 mm thicknessRollers made of high-quality tool steel with Cr plated Heatable roller up to 110°C with a central heating elementThe R2R hot press can be placed into a dual-chamber gloveboxElectric parts are Ar gas compatible The alignment control is optional at the extra cost |

| Rollers -Optional pressure controlled  | Diameter: 200mm (8″)Width: 250mm (10″)Surface Hardness: HRC60-62Warning: Never rolling material > HRC 50Max Rolling Speed: 5.92RPMMax Linear Speed: 60mm/secMax. Heating Temperature for roller Temperature > 120°C rollers may deform and cause pressing to be non-uniform. <110°C for continuous operationOption: Pressure controlled up to 10 metric tone is available at the extra cost |

| Pressing Thickness | 0~2 mm adjustable |

| Dial Gauge Accuracy | 0.01mm |

| Roller Surface Hardness | HRC60-62Never roll materials with hardness > 50HRC |

Temperature Controller | Two temperature controllers enable to control of the upper and lower rollers independently.110 ℃ maximum for less than 1 hour (<100℃ continuously)Recommended heating rate: ~3℃/minutePower of heating element: 400W (total of four heating elements are installed)Precision temperature control with +/- 2.5°C accuracy |

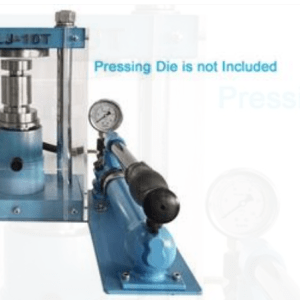

Roll to Roll Fixture  | Two 8″ width feeding rolls to deliver one or two-layer substrate into the hot pressOne winding roll with automatic tension force controlSeparatable roll-to-roll modular for easy shipping and assemblingThe alignment control function is available as an option Note:Proper alignment is required during the installationOptional the rectifying control system to keep better alignment during a roll-to-roll is available upon request (Pic1 right)10T Max Roll to roll with pressure controlled with an electric hydraulic pump is available at an extra cost (Pic. 2, right)     |

| Power | AC 208 – 240V single phase, 50/60 HzTotal: 2400W6 feet power cable is included, but the power plug is not included. |

| Dimensions |  |

| Weight | 200 KG |

| Shipping dimensions | 48″x40″x34″ x2 |

| Shipping weight | 1000 lb |

Operation Video | https://youtu.be/88QrVmgEEcE |

| Compliance | CE CertifiedNRTL or CSA certification is available upon request at an extra cost |

Warranty | One-year limited manufacturer warranty with lifetime supportRusting and damage due to improper storage condition or maintenance are not covered by warranty |

| Application Notes | Never roll materials with hardness > 50HRCIn order to prolong the lifespan of the roller bearings, regular lubrication is recommended Multi-step thickness calendering needed: While calendering the sample sheet, make each calendering decrement of 0.02mm compared to the sheet original thicknessClean the roller surface for each rolling and Use acetone to clean and lubricate when not in use to avoid corrosion |